In your quest for “used pallet racking,” the internet may yield countless results, ranging from individual sellers to established dealers. The real issue with used racking is about more than availability but ensuring it is safe, compatible, expandable, and cost-effective for your needs. Finding a reliable and safe used racking structure while saving money is possible. However, it’s important to be knowledgeable to avoid disappointment and loss of investment. Here we go over some points to consider buying used pallet racking.

Safety Considerations

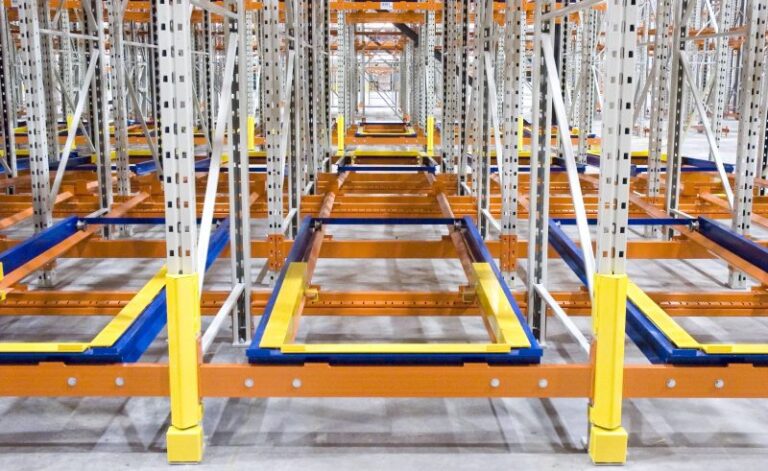

Pallet racking systems are designed to bear immense weights. The system’s overall safety is determined by its components’ condition and suitability, design, engineering, and installation. Any failure in these areas can result in catastrophic accidents, such as a system collapse.

Regulatory and Legal Aspects

Workplace safety, particularly for racking structures, is governed by Occupational Health and Safety, CSA, and Building Codes. Engineers need to interpret these codes and determine the system’s adequacy.

Municipalities utilize Building Permits to ensure engineers have done their due diligence and all regulations and codes have been met.

Above and beyond specific regulations for racking structures, the Criminal Code of Canada and OHS mandate the employer’s duty to provide a safe work environment. Failure to ensure the racking system meets codes can have significant repercussions.

Pallet Rack Capacity

Ensure the used racking has enough capacity for the materials you plan to store. Never assume the existing system will suffice for your needs based on its previous use. The system’s capacity relies on the manufacturer’s stated capacity, the components’ current condition and age, and how the system is designed, as an engineer assesses.

Sizing Factors

Consider the right size for your products and facility:

- Frames: The height should maximize your warehouse space without exceeding it. The frame’s depth should match the depth of your pallet or materials.

- Beams: Ensure they are long enough to store your pallets or materials with appropriate spacing.

Always confirm the system compatibility with your material handling equipment, especially for specialized systems like drive-in or double-deep racks.

Compatibility

When expanding an existing system or combining different materials, compatibility is key. This starts with identifying whether they belong to the same brand or profile. Furthermore, verify that no design or sizing variations could impede proper fit. Consider necessary accessories like row spacers, safety bars, and mesh decks. If the racking isn’t a standard size or a familiar brand, sourcing accessories could be challenging and expensive.

Condition

Avoid components that have been damaged, modified, or repaired without engineering approval. Even minor scratches and dents should be approved by an engineer before using the system.

Appearance

Buying used racking means you’re ready to compromise on appearance. However, make sure the overall condition is satisfactory. Consider factors like labels, cleanliness, and the state of the paint. At Trimet Storage, we ensure that all our used pallet racking is in excellent condition.

Transportation

Ask your vendor to include freight costs in their pricing. This way, they take responsibility for determining all the sizes and weights and how the bundles are loaded onto the trailer.

Vendor Reputation

Investigate the reputation of the seller. If they’re a Material Handling vendor, ask for recent references and confirm they can answer specific questions about the racking’s capacity, condition, and prior use. If you’re buying from an individual, extra caution is necessary. Consider involving a Material Handling professional to assess the materials before purchasing.

Installation

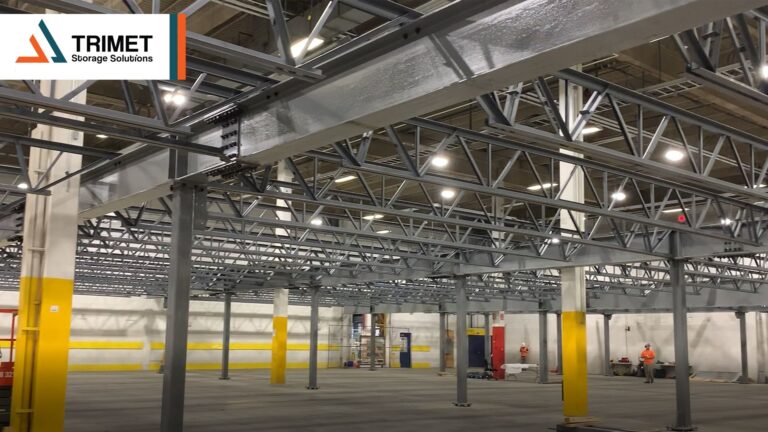

Installation of used materials can be more time-consuming and costly. The extent of this will depend on the racking’s condition and the variety of materials involved. It’s not uncommon for seemingly good components to show deficiencies during installation, leading to delays andadded costs. Trimet Storage Solutions prides itself on being a comprehensive provider for all pallet racking needs. We offer an extensive range of new and used pallet racking solutions, ensuring we can cater to any requirement and budget. Our used racking systems are carefully inspected for quality, safety, and reliability before being listed for sale, providing our customers with cost-effective options without compromising safety or functionality. Meanwhile, our new pallet racking systems feature the latest innovations in the industry, offering peak performance and longevity.

Trimet Storage Solutions is dedicated to providing expert advice and superior products to ensure a safe and efficient racking solution for your needs. Whether you’re buying new or used, we’re here to help. To learn more about our new and used pallet racking systems,