Mezzanines, rack supported mezzanines or work platforms are a fantastic way to use your warehouse’s often-neglected “cube” space. By “cube,” we’re referring to the vertical dimension, not just square footage. You’re paying for the entire internal space of your facility, so why not make the most of it?

Mezzanines can cater to office space, additional manufacturing, or storage operations. The best use of this space includes choosing the ideal construction method for your platform to ensure a safe, efficient workspace. Two primary construction options are considerably less costly than new construction. So, if your business is expanding or your processes are evolving, and you need more space, it’s wise to consider these value-adding alternatives.

The two main construction options are:

- Industrial Work Platform (IWP)

- Rack Supported Mezzanine

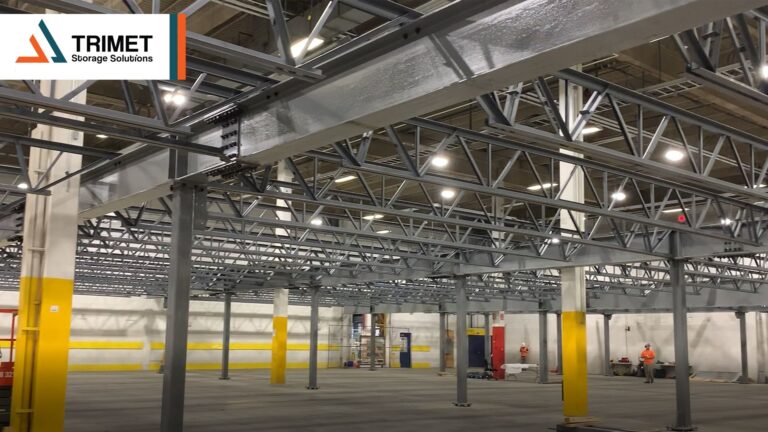

The IWP is a freestanding heavy-duty structure that can be configured to cater to any facet of business expansion. From small standard designs to multi-level custom structures, these bolt-together systems are built to withstand the workload of a bustling operation. Heavy-duty rails, stairs, ladders, lifts, and gates can be integrated into your structure. Several decking options, such as moisture resistance, open grating, or heavy-traffic surfacing, provide the necessary coverage.

Some of the pros inherent in IWP construction include:

- Fewer columns than rack-supported mezzanines

- More flexibility with column placement and design

- More versatility with stair, drop gate, handrail placement, and modifications

- More adaptable to accommodate operational changes, e.g., adding conveyors, carton flow, shelving, workstations, or offices

- Ability to add sprinkler systems to the webbing in joist and girder system modules

While an IWP can be an excellent choice for many applications, there are a few factors to consider before finalizing this option:

- Footings may be needed depending on the number of mezzanine levels and concrete

- IWP is more expensive than rack-supported mezzanines

- Support structure is needed for carton flow or pallet flow applications

- Generally, there is less clearance under the module than in a rack-supported structure

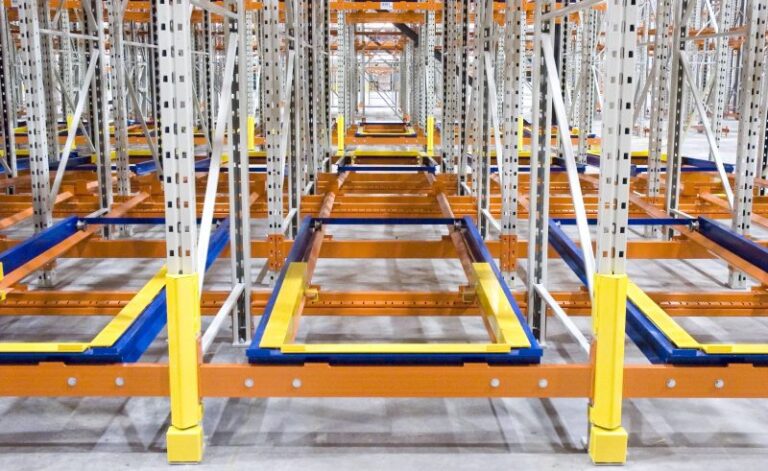

Next, let’s examine rack supported mezzanines. This type of mezzanine can be designed within the pallet racking and over the aisle space or the top of the racking uprights. It is bolted to the uprights to secure the mezzanine frame, and then the decking is fitted to the frame. Pallet storage is accessible below and, on the perimeters, leveraging the added square footage of the mezzanine above, making it a cost-effective use of the pallet rack. Like IWPs, flooring options vary to accommodate the platform function. Similarly, railings, stairs, conveyors, and lifts can be attached to the structure but may require additional structural support beams.

Pros of rack supported mezzanine construction include:

- Racking structure supports carton flow, cantilever shelving, pallet flow, conveyor, stairs, and pallet gates

- More cost-effective than an IWP

- Generally, there is no need for footings when constructing multiple levels

- Visually appealing with the racking system

Things to consider when deciding on rack supported mezzanines:

- More columns than for an IWP

- Less flexibility for future modifications

- Challenging to expand on to the footprint in the cross-aisle direction

The mezzanine is an excellent way to use the space you’re already paying for. Both options are cost-effective compared to new construction, and the downtime to build your new platform can be minimized with proper planning.

At Trimet Storage Solutions, our engineers can assist you in deciding which of these options is the best for your growing warehousing needs. Our design standards ensure that building codes, load-bearing considerations, fire, and safety requirements, and more are included in your complete project package. Call us today!