Push-Back and Pallet Flow Racking are two of the most effective high-density storage systems available for modern warehouses and distribution centers. While both use gravity to move pallets and reduce the need for multiple aisles, they serve very different operational needs. Whether you’re managing perishable inventory that demands First-In, First-Out (FIFO) rotation or looking to maximize space for slower-moving SKUs, understanding the strengths and limitations of each system is essential.

In this guide, we break down how each works, when to use them, and how a smart combination of both can elevate your warehouse efficiency.

What is Push-back Racking System?

Push-back racking is a high-density pallet storage system that maximizes warehouse space without sacrificing product access or increasing handling time. Compared to traditional selective racking, push-back systems can offer up to 90% more pallet positions by storing pallets up to six deep per lane.

How It Works

Push-back racking uses a system of nested carts on inclined rails. Each lane is slightly sloped, allowing gravity to do the work:

Pallets are loaded from the front onto the first cart.

To load a new pallet, the previous one is gently pushed back, making room for the next.

When unloading, the front pallet is removed, and the remaining pallets automatically roll forward.

Forklifts never enter the rack, reducing rack damage and speeding up the handling process.

Key Benefits

Space Efficiency: Requires only one aisle for both loading and picking. No need for a separate access aisle at the rear.

Labor-Saving: Forklift operators don’t have to shift pallets around to access others—eliminating double-handling.

Ideal for Varied SKUs: Each lane typically holds a single SKU, but multiple SKUs can be stored across different lanes.

Fast Throughput: Streamlined loading/unloading helps speed up warehouse operations.

Low Maintenance: Carts are equipped with sealed bearings and large, coated wheels for smooth, durable performance.

Custom Options: Carts can be color-coded and designed for maximum vertical clearance.

Is Push-Back Right for You?

This system is best for Last-In, First-Out (LIFO) inventory, making it less suitable for date-sensitive products. However, with thoughtful layout design, FIFO (First-In, First-Out) configurations are possible.

Push-back is especially effective if:

You need high-density storage

You’re working with multiple SKUs in moderate volumes

Your warehouse layout benefits from reduced aisle count

You’re storing goods in cold or confined spaces, like coolers or freezers

Limitations:

Maximum of six pallets deep per lane

Not ideal for inventory requiring strict FIFO

What is Pallet Flow Racking?

Pallet flow racking—also known as gravity flow racking—is a First-In, First-Out (FIFO) storage system that keeps your inventory moving in the right order. If you’re storing date-sensitive or perishable items, this system ensures that the first pallet stored is the first one picked, making it ideal for industries like food and beverage, pharmaceuticals, or anything with expiration dates.

How It Works

Pallet flow racks use inclined rails with rollers or wheels that allow pallets to move automatically from the loading end to the picking end by gravity. Here’s the flow:

Pallets are loaded at the rear of the system. Gravity takes over; pallets roll forward as the front pallet is removed. Optional braking systems can be installed to control speed, especially useful for fragile or sensitive items like glass or carbonated drinks. This setup delivers high inventory rotation, consistent product flow, and significantly reduces forklift travel time.

Key Benefits

- FIFO Inventory Rotation: Perfect for perishable goods or regulated storage.

- High-Density Storage: Can store up to 25 pallets deep per lane.

- Fast & Efficient: Automatic movement reduces handling time.

- Reduced Damage: Minimal forklift interaction with racking structure.

- Customizable: Optional braking systems for delicate loads.

When to Use Pallet Flow Racking

Pallet flow racking is ideal when:

- You require FIFO for expiration tracking or regulated products.

- You’re handling high-volume, fast-moving inventory.

- You have room for an aisle at both ends (loading on one side, picking on the other).

- You want more pallet positions per bay than push-back can offer.

Keep in mind that pallet flow systems require two aisles—one for loading, one for unloading. But in return, they offer even higher density than push-back rack systems.

Push-Back vs. Pallet Flow Racking: Which System Is Right for You?

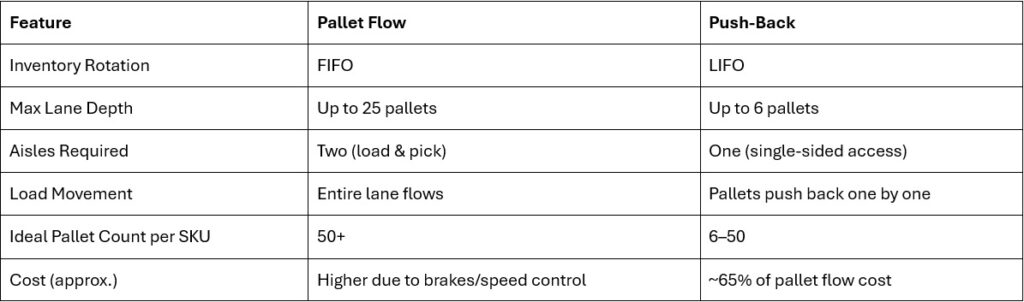

Choosing between push-back racking and pallet flow racking comes down to two key factors: your inventory rotation method and your operational priorities.

If you’re storing perishable goods or date-sensitive inventory, pallet flow is the clear winner. It follows a First-In, First-Out (FIFO) method, ensuring that the oldest inventory is picked first. Push-back racking, on the other hand, is a Last-In, First-Out (LIFO) system—better suited for non-perishable goods where immediate rotation isn’t critical.

While both systems optimize space and reduce aisle count, they serve distinct use cases and can even complement each other. For example, you might install pallet flow racks in a designated cold storage area for high-rotation SKUs, while deploying push-back racks in freezers or against walls to store slower-moving items with fewer pallet turns.

Can you have both?

You’re not locked into a single racking solution. In fact, smart warehouse design often incorporates a hybrid approach, using both systems strategically to support different zones within the facility. For example:

Pallet flow racking for FIFO inventory like dairy, pharmaceuticals, or high-turnover goods

Push-back racking for LIFO inventory or SKU ranges with moderate turnover and limited replenishment needs

Selective or floor storage at the base level, with push-back installed above for dense vertical storage

This modular approach enables maximum flexibility and ensures that each product type is stored in the most efficient, cost-effective manner possible.

Design Considerations

Both systems use inclined rails to move pallets by gravity, but the depth, cost, and structural impact vary:

Pallet flow racks require speed controllers or brakes—especially in deep-lane systems—to prevent product damage. Push-back systems, which move one pallet at a time, generally don’t need braking, making them a more cost-effective option.

Pallet Size, Rack Design & Structural Fit

Don’t overlook the importance of pallet quality. Poor or inconsistent pallets can disrupt flow, especially in pallet flow systems. Push-back racks are best suited for uniform pallet sizes, while some pallet flow designs can accommodate varied loads—giving them an edge in versatile storage needs.

Structural elements, like building columns, also influence system selection. Push-back can work around obstructions, while pallet flow requires clear, uninterrupted lanes.

Final Word: One Size Doesn’t Fit All

No two warehouses are the same—which is why the best solution is rarely one-size-fits-all. At Solico Metal, we help clients evaluate their storage density goals, product mix, and throughput requirements to recommend a tailored solution that may include:

Selective rack for 1–5 pallets per SKU

Push-back racking for 6–50 pallets per SKU

Pallet flow for 50+ pallets per SKU

Pallet shuttles for bulk storage and truckload handling

Each system has its place. The key is knowing when and where to use it.

Need help figuring out your best storage configuration?

Get in touch with Solico Metal’s team of material handling experts—we’ll help you design a system that’s built for your inventory, budget, and growth.