Warehouse real estate isn’t getting cheaper, and “just build another building” rarely flies with the CFO. Two of the most popular racking contenders—Selective and Double-Deep—promise more pallets per square foot without creating forklift gridlock. Here’s a more in-detail comparison:

1. Why do we call it “Selective Racking”?

Selective pallet racking lives up to its name by delivering true “one pallet, one pick.” Because every pallet faces the aisle, forklift operators never have to shuffle loads or play warehouse Jenga, which saves time and reduces product damage.

The system is compatible with nearly any lift fleet. Standard sit-down trucks cruise comfortably through 10- to 12-foot aisles, reach trucks work efficiently in 8- to 10-foot apertures, and Very Narrow Aisle (VNA) equipment can shrink the aisle to just six feet without sacrificing access. That flexibility lets you balance storage density against equipment costs and throughput requirements.

Installation is almost plug-and-play. Uprights bolt down quickly, beams drop into place, safety clips lock, and the rack is ready for product. Once assembled, the structure remains infinitely adjustable; you can reposition beam levels whenever SKUs change size or velocity, all without welding or extended downtime.

Selective racking also remains the most dollar-friendly option in the catalog, offering the lowest cost per pallet position while still providing the strength to handle heavy-duty loads such as steel coils or bulk liquid totes.

In short, this configuration excels in operations juggling a high variety of SKUs with frequent picks—any environment where someone is always calling out, “I need that pallet now.”

Selective pallet racking is the most affordable option per pallet, easy to find used, and ideal for high SKU variety. It works with standard forklifts, handles mixed pallet sizes well, and makes the most of vertical space without complex components.

2. What’s “Double-Deep Racking”?

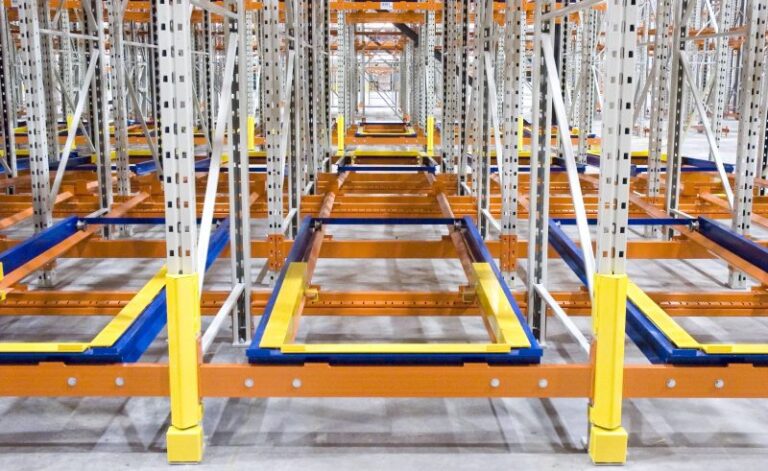

Double-deep racking works by placing one pallet directly behind another, so each lane holds two pallets that face a single aisle. You effectively double your storage density compared with a standard selective setup without sacrificing an extra aisle of real estate.

Because the rear pallet sits beyond the reach of a conventional counter-balance truck, you’ll need reach trucks—or forklifts fitted with pantograph extensions—to retrieve it. That equipment upgrade is the price of entry for the extra cubic efficiency.

The payoff is a system that stores more product per linear foot of rack and frees up floor space you’d otherwise dedicate to extra aisles. Fewer aisles translate into less area to illuminate, sweep, and heat, which shows up as ongoing operational savings.

Double-deep also shines in high-throughput environments. If your fast-moving SKUs routinely ship in pairs or batches, staging them two deep reduces travel time for pickers and keeps product flowing.

Selectivity drops to roughly 50 percent—you must move the front pallet to reach the one behind—but that’s still a major upgrade over bulk-stacking, and many operations can plan inventory so that inconvenience is minimal.

Installation is straightforward: you’re using the same uprights and beams as a selective system, simply arranged in back-to-back pairs. Crews familiar with selective rack will find the learning curve shallow and the changeover quick.

In practice, double-deep racking delivers the best ROI for high-volume operations with a moderate SKU mix—enough variety to need accessibility, but not so many individual items that 50 percent selectivity becomes a bottleneck.

Double deep pallet racking stores pallets two rows deep, increasing storage capacity by reducing aisle space. It requires specialized forklifts with reach or pantograph mechanisms and is best suited for high-volume, low-SKU or identical products. This LIFO system offers 50% direct access, fast stock rotation, and efficient use of space—ideal for operations where maximizing density matters more than full pallet accessibility.

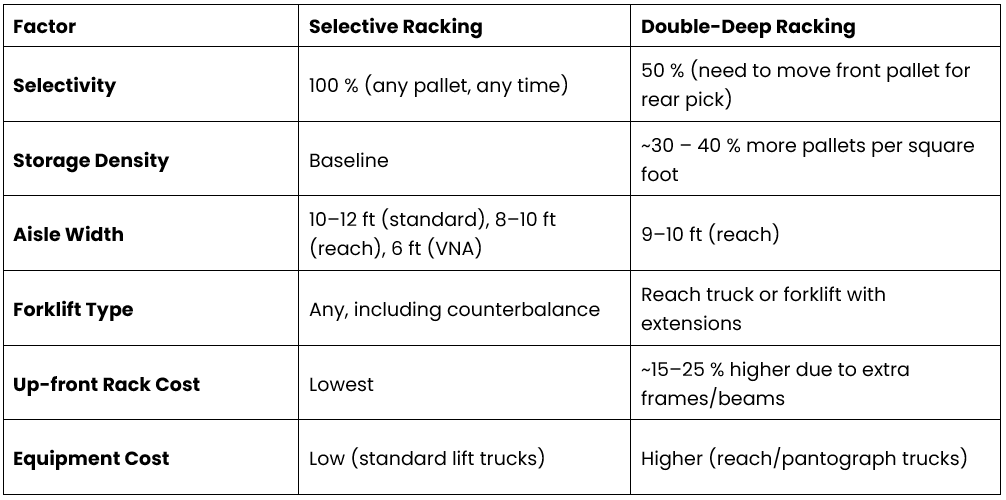

3. Head-to-Head Comparison

4. Choose Selective When:

- You stock hundreds or thousands of SKUs with unpredictable order patterns.

- You require a strict FIFO inventory management.

- You’re cycling product daily and want the absolute fastest pick time.

- You already own a fleet of standard forklifts and aisle space isn’t hand-to-hand combat.

5. Choose Double-Deep When:

- You ship in pairs or batches—think two pallets per SKU, per order, per day.

- Real estate is the bigger headache than forklift upgrades.

- Your WMS or inventory flow can handle 50 % selectivity without drama.

- You’re pushing 85 % occupancy and need ~30 % more slots without adding square footage.

6. The Trimet Takeaway

Selective racking offers unmatched versatility and cost-efficiency, making it an ideal choice for operations with high SKU variety and frequent access needs. Double-deep racking, on the other hand, provides greater storage density and is well-suited for high-throughput environments with more predictable inventory patterns. Choosing the right system is critical—selecting the wrong one can lead to wasted space or inefficiencies in day-to-day operations.

If you’re evaluating your options, the Trimet team can help. We’ll assess your needs, review your layout, and provide a tailored, code-compliant racking solution that balances density, accessibility, and workflow.

Interested in a custom density analysis? Send us your SKU count and a basic layout—we’ll take it from there.