Pallet Rack Safety in Alberta: Design, Maintenance, and Best Practices

In the heart of Alberta, where industries thrive and warehouses are a common sight, pallet rack safety is of utmost importance.

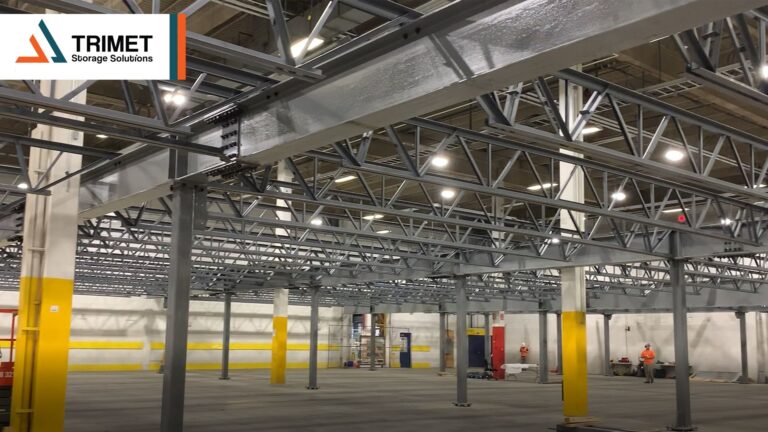

At Trimet Storage Solutions, we understand the unique challenges Alberta businesses face. We emphasize the importance of a well-planned and properly maintained pallet racking system.

Understanding Pallet Rack Hazards in Alberta Warehouses

While system collapses are the most feared, Alberta warehouses face other pallet rack dangers. Falling materials, pallet dislodgement, ergonomic challenges, delayed emergency responses, and material handling equipment traffic are equally concerning.

Designing a System of Pallet Rack Safety for Warehouses

Pallet Rack Safety starts with design. Here’s a blueprint for businesses:

- Load Insights: Accurate load dimensions and weights guide the choice of racking beams and end frames. Factor in Uniformly Distributed Loads (UDL) for optimal safety.

- Aisle Space: The forklift’s specifics determine the minimum aisle width. This is non-negotiable for both productivity and safety.

- Safety Add-ons: Enhance load stability with accessories like mesh decking, safety bars, and post protectors. They also shield the system from potential damage.

- Beam and Frame Dimensions: Ensure they match your pallet sizes to prevent obstructions and collisions.

- Pedestrian Safety: Alberta warehouses are bustling. Use clear floor markings and barricades to guide foot traffic and avert mishaps.

- Depth-to-Height Ratio: A golden rule: the system’s height shouldn’t be more than six times its depth.

Installation Guidelines for Alberta Businesses

With a design in place, adhere to the manufacturer and engineer’s recommendations:

- Anchoring: Frames should be anchored as per the design.

- Beam Levels: Maintain the beam elevations provided. Any tweaks should be engineer-endorsed.

- Installation Specifics: Align rows with the building’s layout. Ensure end frames are level and upright.

- Safety Pins: These are vital. They prevent beams from unintentional dislodgement.

Empowering Your Team

Knowledge is pivotal. Equip your team with the expertise to use the system safely. Regular briefings, documented Safe Work Procedures, and certified training are essential.

Maintenance and Adjustments for Warehouses

Avoid overloading the system. Even with a safety margin, it’s risky. As businesses expand, resist the urge to modify the racking system. Such changes can endanger its capacity and safety.

Routine checks are mandatory. Address any damages immediately. Document all checks and repairs—it’s a testament to your commitment to safety. And, always ensure aisles are clutter-free.

At Trimet Storage Solutions, we champion safety. We’re committed to assisting Alberta businesses in crafting a secure and efficient warehouse environment. Curious about our offerings? Connect with us today.